A key principle of the Health & Safety at Work Act 2015 (HSWA) is the requirement for a systematic risk and hazard management process, to identify potential and actual sources of harm. When risks and hazards are recognised, the university is able to put controls in place to prevent harm to workers. The legislation requires PCBUs (Person Conducting a Business or Undertaking) to take a systematic approach to make workplaces safe and healthy.

There are several generic risks and hazards present in the University environment that you can find more information on using the navigation bar on the left.

Reasonably Practicable

The HSWA legislative term "reasonably practicable" means what can reasonably be done in relation to health and safety, taking into account matters including:

- the likelihood of the hazard or the risk concerned occurring

- the degree of harm that might result from the hazard or risk

- what the person concerned knows, or ought reasonably to know, about:

- the hazard or risk

- ways of eliminating or minimising the risk

- the availability and suitability of ways to eliminate or minimise the risk

- after assessing the extent of the risk and the available ways of eliminating or minimising the risk, the cost associated with available ways of eliminating or minimising the risk, including whether the cost is grossly disproportionate to the risk

The University is primarily responsible for establishing a risk and hazard management system, and are not expected to deal with things that they couldn't possibly have foreseen or controlled.

View the Health and Safety at Work Act 2015

Identifying risks and hazards

The first step in managing a risk or hazard is to identify it. The University of Otago has an online risk assessment and hazard management system, Vault, to identify risks or hazards within the university workplace to create controls. All workers should know how to access the department's register, and how to report a risk or hazard.

What is a risk/hazard?

Hazards are things that exist and can cause harm (such as a drill press), where risk is the combined likelihood of that hazard being in use or circumstance that allows harm. For example, a guarded drill press that is used by a trained and experienced person and it is the right tool for the job is unlikely to cause harm and be used in a same manner i.e. the risk of injury is low. The purpose of risk and hazard management is to ensure that the work that is required to be done, with the tools and processes is managed to minimise the risk of harm to any person on campus.

Report a hazard or incident

All risks and hazards should be reported using the Vault system. All workers and students are able to report a risk or hazard through the Vault online portal.

Managing risks and hazards

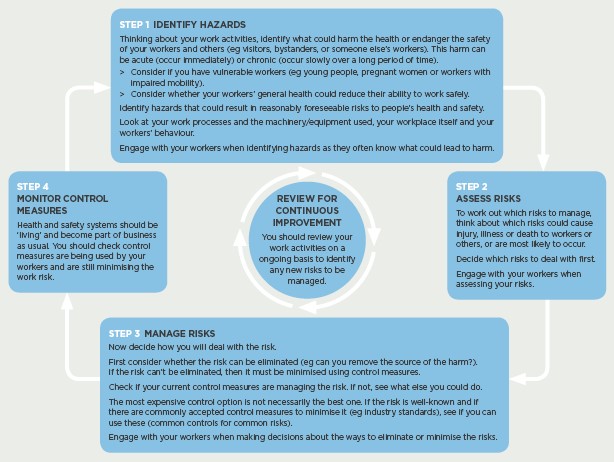

The HSWA focuses on the management of work related risks and hazards, and requires the university to follow this sequence:

- IDENTIFY workplace hazards

- ASSESS risks

- MANAGE risks

- MONITOR control methods

Controlling risks and hazards

When a risk or hazard is identified, it must be assessed for control through elimination or minimisation.

Elimination: This is when the risk or hazard is removed from the workplace, such as removing a hazardous substance that is no longer required. Even though the risk or hazard is removed, it must be recorded in the register. If you are substituting a risk or hazard with another substance or process, be sure to complete the risk and hazard identification for the new process or substance. Record the decision in the register.

Minimisation: Where elimination is impracticable, minimise the risk or hazard through appropriate controls, such as PPE, work organisation factors, etc. This means that the risk or hazard still exists but exposure to the hazard is controlled to manage the risk.

Risk/hazard monitoring

When a risk or hazard is managed by minimisation, it's a requirement to monitor workers exposure to the risk or hazard (in addition to monitoring their health in relation to the exposure). Monitoring the risk or hazard ensures the control is effective.

Surveys that may be required in the university environment include:

- Noise levels

- Lighting

- Air contaminants

- Chemicals

- Radiation

- Air quality

- Biohazards

- Air Temperature

- Asbestos

- Vibration

If any of these risks or hazards are applicable to your department, contact the Health and Safety Team to arrange the necessary monitoring.

Health risks/hazards

When minimisation is used to manage a risk or hazard, the university must monitor worker's health in relation to their exposure to the risk or hazard (with the consent of the worker). Although the university is responsible for health monitoring, the principles of privacy, human rights and discrimination apply.

The University Occupation Health Nurse provides noise monitoring and lung function monitoring. If the risk and hazard register indicates these controls in relation to risks or hazards (e.g. high noise levels, handling of laboratory animals), then the required health monitoring should be in place.

Worker participation

Worker involvement is a key part of the legislation, as workers who do the work are usually aware of the risks and hazards and have ideas on ways of controlling them. Workers are also responsible for themselves, and to ensure their work does not become a risk or hazard to them or any other person.

Find out more about Employee Participation at Otago

Approved codes of practice, guidelines and information

The WorkSafe website has a range of information, including Approved Codes of Practice on managing risks and hazards in specific areas.

Visit the WorkSafe website now

University controls

Where generic or common risks or hazards exists, University health and safety policies have been designed to provide internal guidance on the control standards required. Check the policy database to see if the risk or hazard is covered.

Related info

Key contacts

Andrea McMillan

Director, Health, Safety and Wellbeing

andrea.mcmillan@

64 3 479 7380

Nevan Trotter

Health and Safety Manager

nevan.trotter@

64 3 479 5389