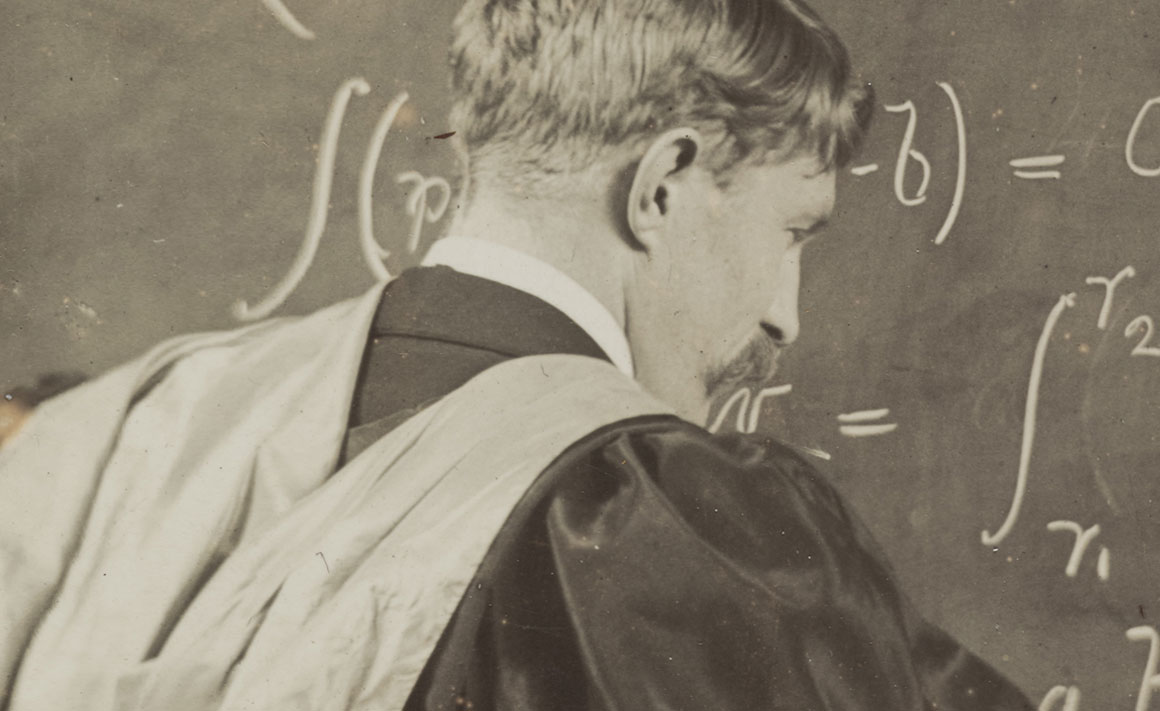

“Today we may not know enough to see the practical bearing of this work, but who dare predict what we shall see tomorrow.”

These are the words of Joseph William Mellor, a self-educated young man who ultimately graduated with a Master of Science degree from the University of Otago in 1899 and became one of the world's most esteemed chemists. A prolific writer, his works include the 16-volume 16-million word Comprehensive Treatise on Inorganic Chemistry, which can still be found in chemistry libraries around the world.

However, he is most famous for his work in the British ceramics industry. Mellor was an innovator and his work did, indeed, have a very practical application. Based in the potteries' heartland of Stoke-on-Trent, his research covered subjects such as the constituents of clays, the performance of firebricks and the behaviour of glazes: he helped famous English potter Bernard Moore develop his signature sang-de-boeuf glaze.

He developed a particular interest in refractory materials – typically heat- and pressure-resistant ceramics used to line furnaces and kilns. He understood that many manufacturing industries were limited by the durability of these materials, and his work on improving their effectiveness was of enormous importance to the British steel industry during World War One.

At the outbreak of the war the importation of refractory linings from Germany and Austria ceased. Mellor quickly developed alternatives to enable the continuation of the steel industry's output.

Such was the significance of his contribution to the war effort he was offered a life peerage, but turned it down saying he had freely given of his scientific knowledge to help his country because his health (at 49 years) prevented him from frontline duty. Mellor remained director of the British Refractories Research Association until he retired and was only the second person elected to the Royal Society for ceramics-related work (the other being 18th century pottery magnate Josiah Wedgwood).

The University of Otago has recently honoured Mellor, naming the refurbished Science 1 building the Mellor Laboratories.

Banner: Dr Joseph W. Mellor, c.1904, Album 518. P2001-059/1-033a. Hocken Collections Uare Taoka o Hākena.Today

1

Techno food

Professor Indra Oey: “We work closely with the food companies, and we know what their problems are and how we can best apply our knowledge to them.”

Translating research to industry, an Otago-led team is showing how pulsed electric fiend technology can add value to plant and animal food products.

Pulsed electric field (PEF) technology is a particular interest of Food Science Professor Indra Oey. Using pulses of electricity to change the cell membranes in animal and plant materials it was originally being used in New Zealand to extend the shelf life of milk and fruit juices. However, Oey saw the potential for a wide range of other applications across various food processing industries and began research on this in 2011.

The Ministry of Business, Innovation and Employment came on board in 2015, funding a major research project as part of its Food Industry Enabling Technology programme.

“If you change the structure of potatoes you can have more controlled release of sugar, more uniform colour formation during frying and reduced oil uptake…”

After three years of initial funding, the ministry was so impressed with what it saw as a clear pathway to transfer the technology to industry that it has funded a further three-year project focusing on potatoes, wine and meat.

“We work closely with the food companies,” Oey says, “and we know what their problems are and how we can best apply our knowledge to them.”

She says that the technology applied to whole potatoes has the potential to produce chips and crisps that are better for the processor and the consumer.

“If you change the structure of potatoes you can have more controlled release of sugar, more uniform colour formation during frying and reduced oil uptake,” Oey explains. “You can also enhance processing efficiency because the softer texture makes the potatoes easier to cut, meaning less waste and the ability to develop different cutting shapes.”

A specially designed PEF machine through which the uncut potatoes pass is being used to trial the technology at a South Island food processing company, in collaboration with the German manufacturer of the equipment, Elea, and the industry association Potatoes New Zealand. Samples are then brought to the University for analysis. Oey says that the research could also readily apply to other tubers such as kumara.

The research on wine will expand on the work by Oey and her colleagues that shows the benefits of passing de-stemmed grapes through a PEF machine, resulting in the faster “maceration” or transfer of colour, flavour and tannins from the grape skin to the wine juice, and enhanced sensorial properties of the wine.

Oey says that they are looking to undertake trials on different grapes and growing conditions at vineyards throughout the South Island.

The research on meat will focus on tenderising low value cuts such as brisket, so that less time and energy are required for “sous vide” processing in which the meat is vacuum-sealed and slowly cooked in a water bath. She says that the PEF technology could also potentially apply to other cuts of beef, and to pork and lamb.

Oey notes that there has been no shortage of volunteers willing to eat free chips and crisps in the interests of science and imagines that wine and meat research will attract a similar response.

She says that they are publishing most of the results of their scientific research and its applications as the work progresses, although some is protected by confidentiality agreements.

Oey and her colleagues are carrying out parallel work on applying the PEF technology to other food materials. She acknowledges the involvement in the research of other universities and crown research institutes and her Otago colleagues and students.

Funding

Ministry of Business, Innovation and Employment

University of Otago Priming Partnership

University of Otago PhD Scholarship

2

Augmented serendipity

It is often acknowledged that the best solutions to complex problems are the simplest ones – or apparently simple.

When looking to ascertain who was working with whom, on what and how within Otago's Business School, Dr Brian Spisak (Management) and Dr Sander Zwanenburg (Information Science) have simply connected the dots.

“Understanding what we all do, who we are collaborating with and on what is fundamental to good organisational management,” Spisak says. “We need to know our knowledge assets. This makes us more relevant within our networks and better able to leverage existing relationships.”

“If we can map all our research interests, our collaborations and networks within the Business School, the wider University and then outside the University, we, as an academic community, can unlock a whole lot of untapped potential.

Zwanenburg says collaborations are often serendipitous – the result of chance conversations, for example. “Brian and I decided that if we can map all our research interests, our collaborations and networks within the Business School, the wider University and then outside the University, we, as an academic community, can unlock a whole lot of untapped potential.”

Their solution is deceptively simple. They have designed the Network for Engagement and Research (NEAR), a user-friendly, highly visual, open-source software application that provides all of this information through “explosions” of interconnecting, colour-coded nodes (or dots). Hovering over each dot reveals scholars' research fields, internal and external relationships, research methods and their sustainable development goals.

The network can also be searched by key words and through a series of drop-down boxes. Group email functionality is another feature, enabling people working in a common area to be easily brought together.

Spisak and Zwanenburg say NEAR offers much potential. As research becomes more complex, a more multidisciplinary, less siloed approach is required: NEAR helps connect people at the individual level, enabling them to work in a more co-ordinated way. It also provides information across specific areas of capability (knowledge assets), and thus provides greater agility in putting together teams for research, funding and external engagement opportunities. It is also valuable as a teaching tool.

The software application is currently in a trial phase across the Business School and the researchers are seeking funding to develop it further. In the future they hope they can incorporate customised versions of NEAR within government agencies, NGOs, consultancies and other organisations looking to optimise networking performance.

Funding

University of Otago

3

Fuelling the future

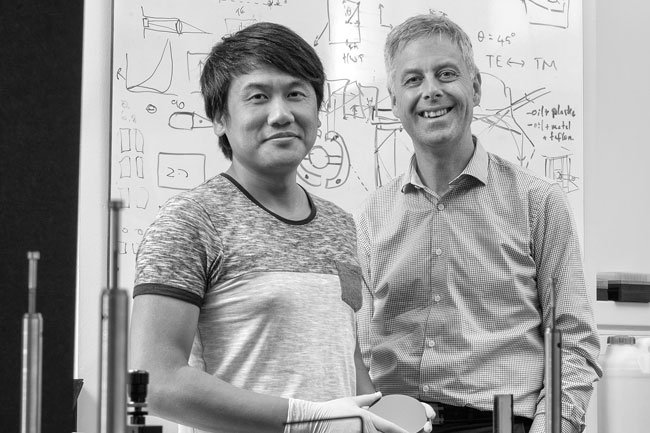

Dr Boyang Ding and Professor Richard Blaikie: They are using their expertise in nano-optics to focus sunlight into semi-conductors to enhance light absorption and improve the efficiency of solar-to-hydrogen production.

It doesn't quite fulfil a motorist's dream of running a car on water, but Otago research has the potential to dramatically reduce the cost of motoring by more effectively using sunlight and water to produce hydrogen.

Research leader Professor Richard Blaikie (Physics) notes that hydrogen is a promising option to replace fossil fuels, but the key is to develop a clean, efficient, cost-effective solution for large-scale hydrogen production.

Blaikie explains that most hydrogen gas is currently produced by “steam-reforming”, using high-temperature steam to split hydrogen from hydrocarbon in fossil fuels such as natural gas, but this in turn produces significant carbon greenhouse gas emissions.

“This has the potential to be more efficient, more cost-effective and more straightforward than existing techniques, and be amenable to small-scale local or large-scale commercial production.”

Blaikie says that producing hydrogen by “electrolysis”, which involves running a large amount of electric current through water to separate out hydrogen, overcomes this disadvantage, but is much more expensive and there are better uses for the electricity.

The Otago-led research seeks to overcome these problems. Rather than using a renewable resource – energy from the sun – to indirectly generate electricity via solar panels and then using the electricity to separate hydrogen from water, the researchers are investigating the use of sunlight to have both the energy conversion and water splitting happen at the one place at the same time.

Research fellow Dr Boyang Ding (Physics), who is doing the hard yards in the laboratory, explains that they are using their expertise in nano-optics to focus sunlight into semi-conductors to enhance light absorption and improve the efficiency of solar-to-hydrogen production.

Blaikie says that the conversion equipment would look like solar panels, but with hydrogen gas lines rather than electricity lines coming off them: the gas would be used on-site or pumped into compressed gas cylinders.

“This has the potential to be more efficient, more cost-effective and more straightforward than existing techniques,” Blaikie says, “and be amenable to small-scale local or large-scale commercial production.”

Ding notes that hydrogen is not only useful as a fuel, but is also important for other purposes such as the production of agricultural fertiliser.

In addition to the obvious benefits to hydrogen users, Blaikie says that New Zealand would gain from the returns on intellectual property and would be well placed to manufacture the conversion panels or benefit from licensing royalties. He says that it would also enhance Otago's reputation for coming up with new technologies and attract further research funding.

“It is a lot of fun to do this kind of research because you are working at a very fundamental level, but you are trying to do something that is very practical and will make a real difference to the world.”

The three-year million-dollar research project is a collaborative effort that also involves Simon Arnold of the National Energy Research Institute in Wellington, Dr Robert Holt and Dr Damian Carder of Callaghan Innovation in Wellington, Professor Yanfeng Zhang of Peking University and Professor Min Qiu of Westlake University in China.

Funding

MBIE Endeavour Fund

4

Mapping gold

Dr Pascal Sirguey: “While drones can appear simple to use, there's a lot more to getting accurate mapping than just pressing the right buttons."

A mapping project using state-of-the-art drone and laser technology has not only helped surveying students hone their skills, it is also playing a part in the conservation of one of Otago's most important historic places.

The University of Otago third-year Surveying project mapped Gabriel's Gully, an historic reserve at Lawrence, Otago, famous as the site of New Zealand's first gold rush in the early 1860s.

These efforts produced a detailed digital map of the reserve, complete with a digital re-creation of an historic stamp battery, and a 3D image never seen before of the mining scarps and historic ruins. This will eventually be uploaded to the DOC and the Lawrence information centre websites.

"Effectively, we've developed a very useful directive for stakeholder engagement for future mapping work.”

Drones provide a revolutionary new way to map topography – it's easier and cheaper than a manned plane and can produce surveys at centimetre resolution and accuracy.

Terrestrial laser scanning is a ground-based imaging method. Distance measurements using laser beams taken in every direction capture the surface shape of objects, buildings and landscapes.

Both technologies have revolutionised surveying science and now support research efforts at Otago, including in snow science, coastal process and geology. They have also enabled new research that may not have been considered without this technology, including crossdisciplinary projects.

Photogrammetric aerial surveying using drones has also been taught for the last three years. Otago Surveying School senior lecturer Dr Pascal Sirguey says its important for the students to learn and assess in the field.

"It's a challenge to achieve and demonstrate accuracy on so many terrestrial laser and drone measurements. While drones can appear simple to use, there's a lot more to getting accurate mapping than just pressing the right buttons," he said.

Incorporating historical and cultural elements introduced another dimension for the student surveyors.

"It's not just teaching students to use the technology – drone mapping is multifaceted and requires more planning and stakeholder discussion than traditional mapping methods. Project management to address logistics, regulations, safety and sometimes wildlife management is, therefore, as important to a project's ultimate success as the technical mapping skills.

“We're pleased that collaborations to map Gabriel's Gully, alongside other projects, have created strong links with many groups and local communities, including DOC.

"Effectively, we've developed a very useful directive for stakeholder engagement for future mapping work. We are also rewarded by the development of maps and survey products with high standards that are valuable for the local community, as well as enabling new collaborative research," Sirguey says.

Shay Van Dur Hurk (DOC ranger, recreation and historic, Coastal Otago) says the drone captured and recorded features that will be extremely useful for planning future conservation and restoration work.

"But this also helps us tell a strong story about an important part of our heritage in a place that is out of the way for many people to actually visit – a picture is worth a thousand words and a 3D image is particularly valuable," he said.

"We love that this historic story is being told with the ingenuity of clever technology and some smart students, and are stoked at our relationship with the Surveying School.”

Funding

University of Otago